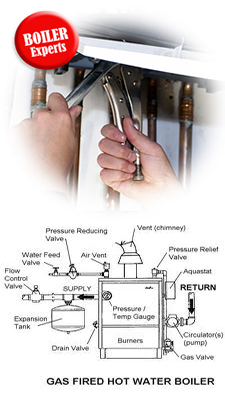

Boiler warmness switch surfaces ought to be stored smoothly to offer secure and reasonable boiler operation. In this phase, we can describe the techniques and processes concerned in fireplace and waterside cleansing, which is also used by boiler repairs coventry .

Cleaning Boiler Firesides

Excessive fireplace deposits of soot, scale, and slag purpose the subsequent conditions: decreased boiler efficiency, corrosion failure of tubes and elements, decreased warmness switch rates and boiler capacity, blocking off of fuel line passages with excessive draft loss and immoderate fan energy consumption, and hearthplace hazards. Methods for cleansing boiler firesides encompass cord brush and scraper cleansing, warm-water washing, moist-steam lancing, and sweating.

Wire Brush and Scraper Cleaning

When an excessive amount of soot is deposited and the passages grow to be plugged, hand lancing, scraping, and combing are commonly used. Special equipment required for attaining between the lanes of tubes can be crafted from flat bars, sheet steel strips reduced with a saw-toothed edge, rods, and comparable devices. Some boilers have one-of-a-kind sizes of tubes, so you want numerous sizes of brushes and scrapers to smooth the boiler tubes. The brushes or scrapers are mounted to a protracted handle, typically a chunk of pipe, inserted and pushed via the tubes. When you’re cleansing the passages, be very cautious now no longer to attain or gouge the tubes due to the fact it could cause weakening and rupturing of tubes below strain.

Hot-Water Washing

This approach of cleansing is regularly used to smooth first-rate heaters, economizers, and different sections of the steam generator which might be hard or not possible to attain with the aid of using brushing or scraping. The water can be carried out with hand lances and/or boiler soot blowers. Dryout the boiler placing without delay after water washing to lessen harm to the refractory and different elements of the placing. Safety is continually paramount; therefore, continually be careful whilst washing boiler firesides. Some precautions you have to examine are as follows:

- Wet the kettle obstinate and protection as low as feasible. Introduce material safeguards or drains in which suitable to diminish the wetting of refractories.

- Safeguard electric gadgets from water hurt.

- Give exceptionally significant orders and insurance gadgets for laborers.

- Give a packed air spear to relax the scale after water washing.

- Give an alright gadget to warm and siphon the new water. The water has to be heated and maintained at a temperature near approximately a 150°F, due to the fact water exceeding this temperature can not be dealt with correctly and efficiently. However, due to the fact bloodless water does now no longer smooth satisfactorily, you need to hold the water temperature as near as 150 ranges as viable. A water strain of 200 to 250 psig has to be supplied on the cleansing lances or soot blowers. The water jets ought to penetrate the tube banks and strike with sufficient pressure to interrupt the slag accumulations.

- Start the water washing on the pinnacle of the unit and paint down.

- The unit ought to be dried out without delay after washing.

Wet-Steam Lancing

The moist-steam lancing approach is much like the new-water approach besides that moist steam is used as opposed to warm water. The steam has to be moist and at a strain of 70 to 150 psig. The unit ought to be dried out without delay after lancing is completed.